The rubber manufacturing market is actually a dynamic landscape, regularly evolving to fulfill the calls for of varied sectors like automotive, development, and purchaser merchandise. As companies try for increased effectiveness, diminished waste, and Improved item quality, the necessity for Superior rubber chopping methods hasn't been additional vital. In 2025, the rubber cutting equipment industry is ready to witness groundbreaking innovations which will redefine precision and productiveness. Whether you might be producing intricate automotive seals, strong industrial conveyor belts, or tailor made-designed rubber factors, buying a state-of-the-artwork reducing device is now not just an alternative—it's a strategic vital. this information meticulously analyzes the very best five rubber slicing devices poised to dominate the marketplace in 2025, ranging from completely automated CNC systems to significant-benefit, consumer-helpful styles. Prepare to find out the perfect Remedy to enhance your output procedures and obtain a aggressive edge. If your business is here seeking a cnc leather-based slicing machine manufacturer, Then you certainly've come to the proper position. let us dive in!

Table of contents:

LatheGlobal SK1600: The completely Automated CNC Revolution

NauticExpo Mecanumeric: Rugged dependability for Harsh Environments

DirectIndustry OP srl: superior-velocity Rotary slicing for Mass Production

Barwell Strip Cutter: flexibility and financial state in Strip reducing

REMA-TIPTOP design 32: Portability and Affordability for more compact Operations

LatheGlobal SK1600: The totally automatic CNC Revolution

https://latheglobal.com/products/cnc-cutting%EF%BC%8Crubber-cutting-machine-with-fully-automatic-felt-leather-cutting-sk1600

manufacturer Overview: LatheGlobal has recognized by itself as a leader in CNC cutting technological innovation, continually pushing the boundaries of innovation and performance. Their determination to excellent, precision, and automation has acquired them a loyal purchaser foundation across a variety of industries.

crucial Features and Added benefits:

The LatheGlobal SK1600 is not merely a rubber reducing machine; It truly is an extensive manufacturing Answer. This absolutely automatic CNC system is created to handle a big selection of materials, such as rubber, felt, and leather-based, rendering it an exceptionally adaptable asset for organizations with diverse product or service traces. The SK1600 distinguishes by itself through many essential strengths:

clever CNC System with AI Optimization: At the heart of the SK1600 lies a complicated CNC procedure run by innovative AI algorithms. This system optimizes slicing paths in actual-time, analyzing content properties and geometry to minimize waste and improve efficiency. consumers have reported a reduction in product squander of up to 20% when compared to regular slicing approaches. The AI also learns from Each and every chopping operation, repeatedly refining its algorithms to further improve general performance over time.

Modular design and style for Unparalleled Flexibility: The SK1600 features a modular structure that permits for speedy Instrument adjustments and customization. This versatility is vital for corporations that take care of sophisticated shapes and varying material thicknesses. The equipment could be conveniently configured with distinctive reducing heads, blades, and add-ons to support a variety of cutting responsibilities. The modularity also simplifies routine maintenance and updates, making certain that the device continues to be up-to-date with the most recent technological advancements.

Energy-Efficient Procedure: In today's environmentally mindful environment, Electrical power efficiency is often a crucial factor. The SK1600 is engineered to minimize Electricity consumption without compromising general performance. in comparison with traditional rubber chopping equipment, the SK1600 boasts a 35% reduction in Electrical power use. This interprets into substantial Expense financial savings over the device's lifespan and contributes to a far more sustainable manufacturing operation.

Unwavering Precision: Precision is paramount in rubber producing, wherever even minor deviations can lead to defects and squandered products. The SK1600 delivers millimeter-degree precision, making sure that each Reduce is exact and dependable. This amount of precision is essential for manufacturing significant-top quality elements that meet up with stringent industry specifications.

consumer-helpful Interface: Despite its Sophisticated capabilities, the SK1600 is built with user-friendliness in your mind. The intuitive interface causes it to be straightforward for operators to software chopping paths, keep an eye on functionality, and troubleshoot troubles. detailed education and aid are also furnished to make certain end users can immediately master the machine's functionalities.

automated Material Feeding and Unloading: decrease labor costs and enhance throughput While using the SK1600's automated content handling technique. This system can quickly feed and unload products, minimizing downtime and enabling for steady, unattended Procedure.

best apps:

The LatheGlobal SK1600 is Preferably suited for suppliers of automotive parts, significant-conclude sealing options, and personalized-designed rubber products. Its precision, flexibility, and automation abilities allow it to be a important asset for organizations that need the very best levels of quality and efficiency. should you are looking for an automatic rubber chopping equipment company, LatheGlobal will probably be your alternative.

NauticExpo Mecanumeric: Rugged trustworthiness for Harsh Environments

https://www.nauticexpo.com/prod/mecanumeric/product-64198-561025.html

brand name Overview: NauticExpo Mecanumeric makes a speciality of offering durable and reliable slicing remedies for demanding industries, notably the maritime and heavy industrial sectors. Their equipment are renowned for their ability to face up to harsh problems and produce constant performance.

essential capabilities and Added benefits:

The NauticExpo Mecanumeric vibration knife chopping program is built to endure the rigors of difficult industrial environments. This device is engineered that has a center on durability, dependability, and slicing overall performance.

Corrosion-Resistant style and design: developed especially for humid and corrosive environments, this slicing system boasts a robust design that resists rust and degradation. All critical parts are dealt with with protective coatings to ensure very long-lasting overall performance, even in essentially the most tough ailments.

High-energy Cutting abilities: This device delivers exceptional reducing electric power, quickly handling rubber composite components nearly 50mm in thickness. The large-torque cutting head ensures cleanse, exact cuts without having tearing or deformation.

true-Time Monitoring procedure: The integrated sensor program presents authentic-time suggestions on blade have on and effectiveness, allowing operators to proactively address possible concerns in advance of they lead to downtime. This predictive upkeep capacity aids reduce interruptions and optimize efficiency.

person-welcoming Interface: The intuitive user interface simplifies Procedure and allows for straightforward programming of reducing parameters. The method also includes a library of pre-established slicing profiles for widespread resources, streamlining the setup approach.

Robust Safety characteristics: Safety can be a best priority in industrial environments. This slicing method is provided with detailed security attributes, like emergency end buttons, gentle curtains, and interlocking guards, to safeguard operators and forestall mishaps.

best programs:

This cutting process is beautifully suited to the manufacture of marine seals, rubber elements for port tools, and also other significant-responsibility purposes in which durability and trustworthiness are paramount.

DirectIndustry OP srl: High-Speed Rotary slicing for Mass manufacturing

https://www.directindustry.com/prod/op-srl/product-17876-1076745.html

manufacturer Overview: OP srl, an Italian producer, is recognized for its experience in building and developing large-pace cutting equipment for mass production apps. Their equipment are noted for their efficiency, precision, and trustworthiness.

vital attributes and Positive aspects:

The DirectIndustry OP srl rotary chopping device is engineered for prime-volume creation, delivering Fantastic pace and accuracy. This machine is perfect for suppliers trying to find To optimize throughput and minimize manufacturing expenditures.

Dual-Axis Synchronization engineering: This device utilizes State-of-the-art twin-axis synchronization technological know-how to attain a 40% boost in slicing performance when compared to traditional rotary cutters. The synchronized motion from the chopping head and material feed ensures easy, specific cuts at substantial speeds.

exact Pressure Command: sustaining constant stress is critical when reducing dense rubber materials. This device features a classy pressure Manage method that forestalls deformation and guarantees clear, clean cuts whenever.

Compact Footprint: suitable for Place-constrained environments, this rotary cutter offers a compact footprint that minimizes floor Area specifications. This makes it perfect for smaller and medium-sized factories exactly where House is at a top quality.

Continuous Internet Processing: The device is meant to manage constant rolls of material, allowing for for uninterrupted creation runs. This function is particularly advantageous for companies of conveyor belts and rubber gaskets.

Automated rigidity Regulate: The integrated rigidity Command process maintains reliable materials rigidity all over the slicing course of action, blocking wrinkles and guaranteeing accurate cuts.

best Applications:

This rotary reducing equipment is perfectly-suited to the mass creation of conveyor belts, rubber gaskets, together with other large-volume rubber elements.

Barwell Strip Cutter: flexibility and economic climate in Strip Cutting

https://barwell.com/products/strip-cutter/

brand name Overview: Barwell, a long-set up British firm, makes a speciality of providing flexible and inexpensive rubber processing remedies. Their Strip Cutter is recognized for its simplicity, dependability, and simplicity of use.

Key attributes and Rewards:

The Barwell Strip Cutter is a flexible and value-productive Answer for slicing rubber strips of varying widths. This machine is ideal for firms that require overall flexibility and affordability within their strip slicing operations.

Adjustable Width Settings: This device permits fast and simple adjustment of strip width from 1mm to 200mm. The adjustable die program simplifies changeovers and minimizes downtime.

minimal-Maintenance style and design: The simplified mechanical structure minimizes upkeep specifications and minimizes the risk of breakdowns. This translates into lower running costs and increased uptime.

silent Procedure: using a sound amount below 75dB, this strip cutter makes a far more cozy and successful working atmosphere.

easy Operation: The clear-cut design would make the machine uncomplicated to function, even for inexperienced customers. minimum training is needed to get started.

strong building: created to withstand the calls for of industrial environments, this strip cutter contains a strong development that assures lengthy-Long lasting general performance.

excellent programs:

This strip cutter is ideal for the preliminary processing of rubber tubing, sealing strips, and other strip-formed rubber parts.

REMA-TIPTOP Model 32: Portability and Affordability for scaled-down functions

https://www.rema-tiptop.com.au/product/rubber-cutting-machine-model-32/

brand name Overview: REMA-TIPTOP is a worldwide leader in providing remedies for conveyor belt maintenance and rubber processing. The Model 32 transportable slicing device is made for affordability, simplicity of use, and portability.

crucial options and Positive aspects:

The REMA-TIPTOP product 32 moveable cutting device is a price-efficient and consumer-welcoming Remedy for small to medium-sized companies. This machine is made for portability, simplicity of use, and affordability.

a single-contact Procedure: The simplified controls make the machine uncomplicated to function, even for inexperienced users. Minimal training is required to begin.

Lightweight and Portable: The lightweight style and design allows for simple transportation and setup in different spots. This makes it perfect for enterprises that will need to maneuver the equipment amongst workshops or career web sites.

Durable Blade: The carbon metal blade is made for very long-Long lasting efficiency, cutting down the need for Recurrent replacements.

reasonably priced selling price: The product 32 delivers a wonderful price proposition, providing responsible cutting general performance at an affordable cost level.

protection functions: The machine is provided with security attributes for instance a blade guard and unexpected emergency quit button to guard operators.

great purposes:

This moveable reducing machine is well-fitted to mend retailers, tailor made fabrication shops, and compact-batch generation runs.

The rubber chopping technological know-how landscape in 2025 is characterised by a center on intelligent automation, Strength performance, and versatile output capabilities. from your completely automated CNC innovations of LatheGlobal to the light-weight structure of REMA-TIPTOP, the enhancements in rubber chopping technological know-how are enabling enterprises to improve their generation processes and reach new amounts of performance and high-quality.Whether you involve significant-precision reducing for sophisticated geometries or Charge-helpful solutions for mass creation, the equipment talked over in the following paragraphs present trusted and impressive solutions. As you Appraise your slicing wants and try to enhance your operations, contemplate exploring the Innovative options offered by computerized rubber slicing device companies like LatheGlobal; they will let you unlock the total prospective within your rubber producing processes.

Joshua Jackson Then & Now!

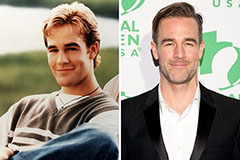

Joshua Jackson Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!